Prototyping and Sampling

Accelerate Design Cycle Time

Validate concepts early and often with production quality prototypes.

Minimize Warranty Risks and Recalls

Catch design, manufacturing, or operational concerns before full scale production.

Beat the Competition

Iterate designs more quickly, enabling you to fully develop products faster than competition with lower development costs.

Boyd Spotlight Series – Engineering Tech

(View transcript)

Prototype Design with the Boyd Engineering Team

Boyd’s mechanical, thermal, electrical, industrial and tooling engineers are specialized in integrating a broad range of technologies into a single component, bringing together environmental sealing, thermal management and protection solutions. Engineers at Boyd are adept at innovative problem-solving, advanced modeling capabilities, and trained in design techniques that allow for a smooth transition from concept to prototype to production. Boyd prototyping accelerates your new product introduction processes by decreasing the number of prototyping cycles prior to mass production runs.

Our engineers partner in a relationship to suit their customers’ needs- acting as a consultant, an integrated part of your engineering team, or fully designing and prototyping solutions for you. By partnering with our engineering team, you benefit from integrated solutions for more optimized prototypes built to exacting requirements. We help you accelerate your time-to-market and broaden your access to innovative solutions while decreasing development cycles and costs.

Quickly Evaluate Your Concept with Prototyping

Repeatedly validating your design is a vital step when designing a high-quality, innovative product, quickly and cost effectively. Accelerate design lead times, reduce R&D costs, and seamlessly transition your idea from concept to reality with Boyd’s prototyping capabilities.

For a fraction of the price and lead time required for production parts, Boyd’s prototypes let you quickly evaluate your concept and can easily allow for multiple design iterations. Testing designs with prototypes is a critical step in creating innovative products and developing smart, efficient, and cost-effective manufacturing processes. Boyd can develop a prototype of your design and help transition it into full production.

Fully functional prototypes can also enhance your marketing campaigns as design samples, internal presentations, and tradeshow presence.

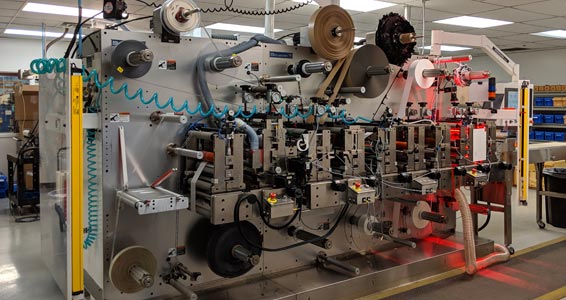

Precision Converting Prototyping

Transform adhesives and other raw materials into precision converted components like gaskets and seals, EMI/ RFI shielding, noise and vibration dampers.

Processes:

- Laser prototyping

- Waterjet cutting

- RTV tooling/urethane casting

- SLA (stereolithography)

- Multi-layer / advanced material stack-ups

- CNC die-less rapid prototyping

General Prototyping Capabilities

- 3D printing/ additive manufacturing – metals & polymers

- CAD modeling

- Custom hand or automated assembly

- Pressure testing

- Rapid tooling/production

Metal Fabrication Prototyping Processes

- CNC machining

- Dip brazing

- Friction stir welding

- Internal component machining

- Internal heat pipe fabrication & testing (groove, screen mesh and sintered powder)

- Metal casting

- Metal coating

- Post-processing & finishing

- Sheet metal fabrication

- Vacuum brazing

- Welding (TIG, MIG, plasma, inert gas, braze), including aerospace qualified weld capability

- Soldering and brazing (torch, vacuum, controlled atmosphere)

- Wire EDM (electrical discharge machining)

Example Products:

- Die-cut components

- Nameplates

- Graphic overlays

- Labels

- Membrane switches

- Integrated displays

- Elastomer keypads

- Printed circuit boards

- Surface-mount technology components

- Decorative parts

- Digital overlay printing

- Polycarbonate embossing

- Conductive ink printing

Have questions? We’re ready to help!